2025-09-30 389

Whether you’re mapping out inventory zones in a warehouse, aligning display racks in a retail store, or marking safety pathways in a factory, straight, even lines are non-negotiable. But traditional methods—chalk lines, tape measures, or string—are messy, time-consuming, and prone to error. A Laser Line Projector for Ceiling Installation solves this: it casts crisp, consistent laser lines from above, turning hours of tedious work into a 15-minute task.

Noparde’s lineup of line laser projectors stands out here, with models built for commercial use—from warehouses to retail floors. Below, we’ll share pro tips for flawless ceiling installation, real-world stories of how Noparde’s projectors transformed spaces (like safety line projector and laser lines for warehouse), and why these tools are a game-changer for anyone needing precise alignment.

Installing a laser line projector from the ceiling isn’t complicated—but small mistakes can lead to crooked lines. Follow these steps to get it right:

First, pick a ceiling mount that matches your space. Noparde includes adjustable metal mounts with most projectors—ideal for drop ceilings, concrete ceilings, or exposed beams. For uneven ceilings, use a mount with a 360° swivel (Noparde’s mount tilts ±10°) to level the projector. “A wobbly mount means wobbly lines,” says Jake Miller, a warehouse manager who installed Noparde’s projectors. “We used Noparde’s heavy-duty mount on our concrete ceiling, and it hasn’t shifted in 6 months.”

Most people skip calibration—but it’s the key to even lines. Noparde’s projectors have a built-in bubble level; use it to ensure the unit is perfectly horizontal. For extra precision, project a test line onto a wall first: if it’s curved or uneven, adjust the mount until the line is straight. “We tested ours on a blank wall before locking it in,” says retail manager Lila Cruz. “It took 2 minutes, and it saved us from redoing the entire display layout.”

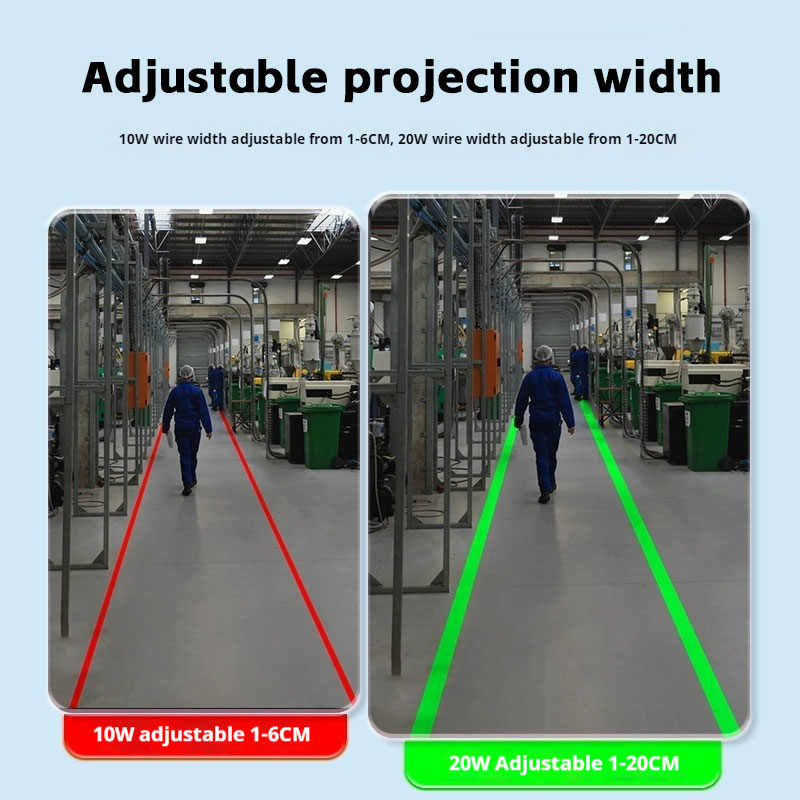

Ceiling height affects line brightness. For warehouses (10–20ft ceilings), use Noparde’s high-lumen model (2,000 lumens) to ensure lines cut through dust and overhead lights. For retail stores (8–12ft ceilings), a 1,500-lumen projector works best—bright enough to see, but not overwhelming. Noparde’s projectors let you adjust brightness (no tool needed) to fit your space.

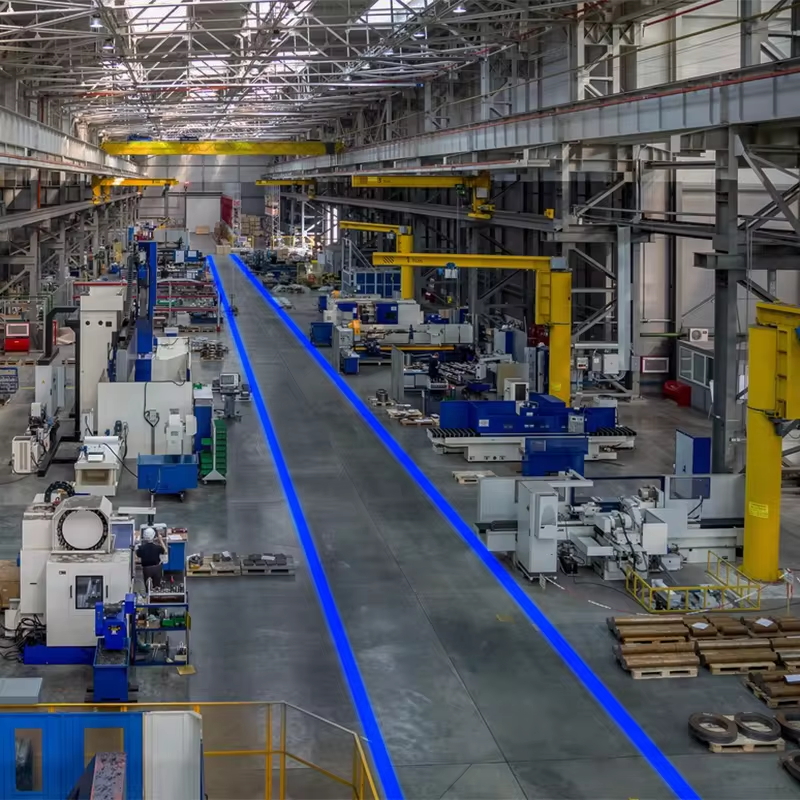

If you’re using multiple projectors (e.g., for a large warehouse), map out coverage zones first. Noparde’s laser lines for warehouse have a 120° projection angle—so one projector covers about 30ft of space. Space units 25ft apart to avoid overlapping lines (overlaps cause dim, blurry spots). “We drew a quick map of our warehouse, marked where each projector would go, and had zero overlaps,” Jake says.

Jake’s 50,000-square-foot distribution warehouse in Dallas struggled with forklift-pedestrian collisions. “We used chalk lines to mark pedestrian pathways, but they faded in a week and got smudged by pallets,” he says. “We had three near-misses in two months—forklift operators couldn’t see the lines.”

Jake installed Noparde’s safety line projector (a ceiling-mounted line laser) to cast bright red lines along pedestrian pathways. The projector runs 24/7, and its dust-resistant lens stays clean even in the warehouse’s dusty air. “Within a month, near-misses dropped to zero,” Jake says. “Forklift operators see the red lines from 50ft away, and employees know to stay within them. We even added a second projector to mark forklift zones—now the floor looks like a ‘traffic grid’ that everyone follows.”

The projector’s durability impressed him too: “We had a pallet fall near one unit, and it didn’t break. Noparde’s tough plastic casing held up, and the line stayed straight.”

Lila’s 10,000-square-foot clothing store in Austin rearranges displays every month. “Setting up racks with tape measures took two employees four hours—we’d always end up with crooked rows,” she says. “Customers would comment on it, and it made the store look unprofessional.”

Lila used Noparde’s floor line projectors (ceiling-mounted, casts blue lines) to mark rack positions. “Now, one employee sets up 20 racks in 45 minutes,” she says. “The blue lines are bright enough to see under store lights, and they never fade or smudge. Our displays are perfectly straight, and customers say the store looks ‘neater and easier to shop in.’”

She adds: “We even use the projector for seasonal displays—at Christmas, we cast green lines for tree and decoration placement. It’s saved us so much time.”

Raj’s electronics assembly factory in San Jose needed to align circuit board stations. “We used string to mark assembly lines, but it sagged in our factory’s AC drafts—stations were always off by an inch or two,” he says. “This caused errors in assembly—we had to redo 10% of our work.”

Raj installed Noparde’s virtual line projector (ceiling-mounted, casts green lines) to mark station edges. The projector’s anti-drift technology keeps lines straight (no sagging, no shifting) even with air flow. “Our assembly error rate dropped to 1%,” Raj says. “Workers can see the green lines clearly, so stations are perfectly aligned. We also use the projector to mark inventory shelves—now shelves are straight, and we can fit 15% more products.”

Traditional line lasers are flimsy, dim, and hard to install—but Noparde’s models are built for commercial use. Here’s why they’re better:

Noparde’s laser lines have a 0.1mm accuracy rating—so lines are straight to the millimeter. Unlike cheap lasers that “drift” (shift over time), Noparde’s anti-drift tech keeps lines in place for 8+ hours. “Our assembly lines are still aligned after a full workday—no adjustments needed,” Raj says.

Noparde’s projectors have an IP65 rating—dust-tight and water-resistant. They work in temperatures from -4°F to 140°F, making them ideal for cold warehouses, hot factories, or humid retail stores. “We have a projector in our cold storage (38°F), and it never freezes up,” Jake says.

Most Noparde models have both plug-in and battery options. The battery lasts 12 hours (great for temporary setups, like pop-up stores), and the plug-in option works 24/7 (perfect for warehouses). “We use battery power for our seasonal displays and plug-in for permanent pathways,” Lila says.

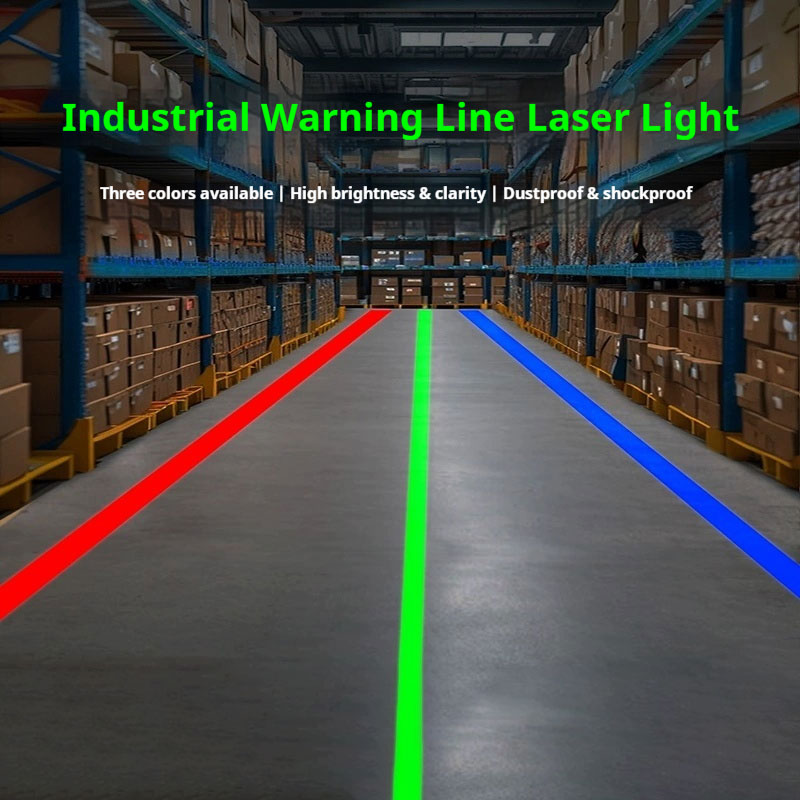

Noparde offers red, blue, and green lines—each for different uses. Red is best for safety (high visibility), blue for retail (softer on the eyes), and green for factories (cuts through bright lights). “Green was perfect for our factory—our overhead lights are bright, but the green line still stands out,” Raj says.

You might wonder: “Why not use a floor-mounted laser?” Ceiling-mounted projectors have three big advantages:

“Floor lasers were a nightmare—forklifts kept hitting them,” Jake says. “Ceiling-mounted Noparde units are out of the way, and the lines never get blocked.”

Whether you’re running a warehouse, a retail store, or a factory, straight lines aren’t just about “looking neat”—they’re about safety, efficiency, and accuracy. Noparde’s Laser Line Projector for Ceiling Installation turns tedious, error-prone work into a quick, easy task—with lines that stay straight, bright, and durable.

Jake, Lila, and Raj’s stories prove it: these projectors don’t just save time—they save money (fewer accidents, fewer errors) and make spaces better for everyone. If you’re tired of crooked chalk lines, smudged tape, or sagging string, it’s time to switch to Noparde.

Ready to get straight lines? Grab a Noparde laser line projector today—and see the difference precision makes.